50 Tons 60 Tons 100 Tons Extrusion Molding Processing Cooling Water Air Cooled Chiller

As a professional water chiller manufactuer in China, we can supply kinds of chiller solution according to your different working need, OEM is accept, if this series is not workable for you, please feel free send news to us.

As a professional water chiller manufactuer in China, we can supply kinds of chiller solution according to your different working need, OEM is accept, if this series is not workable for you, please feel free send news to us.

Our Product Range

(1).The Temperature Range:-40ºC to +35ºC.

(2).Cooling Capacity Range: 2 RT to 500RT / 7 kw to 1750kw / 6020Kal to 1505000Kal

(3). The Refrigerant: R22/R404a/R134a/R507c.

(4). We can also produce the chiller according to your requirements.

(1).The Temperature Range:-40ºC to +35ºC.

(2).Cooling Capacity Range: 2 RT to 500RT / 7 kw to 1750kw / 6020Kal to 1505000Kal

(3). The Refrigerant: R22/R404a/R134a/R507c.

(4). We can also produce the chiller according to your requirements.

1. Technical Parameter for 50 Tons 60 Tons 100 Tons Extrusion Molding Processing Cooling Water Air Cooled Chiller

| Model | MG-200CS | |

| Power Supply | 3 Phase-380V-50Hz | |

| Outlet Temperature range | +7 deg C ~+35 deg C can be control | |

Cooling Capacity | Kw | 220 |

| Kcal/h | 189200 | |

| Tons | 62.6 | |

| Refrigerant | Type | R407c |

| Control type | Thermostatic expansion valve | |

Compressor | Type | Semi-Hermetic screw |

| Quantity | 1 | |

| Power(kw) | 74 | |

Evaporator | Type | Shell and tube |

| Chilled water flow(m3/h) | 38 | |

| Inlet/outlet pipe dia.(mm) | 3" | |

Condenser | Type | High efficiency aluminum finned type |

| Cooling air flow(m3/h) | 80000 | |

| Power(KW) | 1.5*4 | |

| Dimension | L*W*H(mm) | 3300*1450*2150 |

| N.G | Kg | 3200 |

| Protection system | High/Low Pressure protection, Phase-sequencing Protection, Overload Protection, Overheat Protection, Water flow protection, Anti-frozen protection. | |

| Air Cooled Screw Chiller Normally Temperature Series( Single System) | |||||||

| Model | MG-150C | MG-170C | MG-250C | MG-300C | MG-450C | MG-530C | |

Cooling Capacity | USRT | 40.4 | 46.9 | 76.8 | 93.8 | 127.9 | 150.7 |

| Kcal/h | 122120 | 141900 | 232200 | 283800 | 387000 | 455800 | |

| KW | 142 | 165 | 270 | 330 | 450 | 530 | |

| Power | 3PH-380V-50Hz | ||||||

Refrigerant | Type | R22/R407C | |||||

| Control | Thermostatic expansion valve | ||||||

Comperssor | Type | semi-closed screw type | |||||

| kw Power | 48 | 55 | 86 | 106 | 142 | 165 | |

| Start | Y-△ | ||||||

| Capacity | 25%-50%-75%-100% | ||||||

Evaporator | Type | High efficiency copper tube shell and tube type | |||||

| m³/h Flow | 24 | 28 | 46 | 57 | 77 | 91 | |

Inlet/outlet | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | |

Condenser | Type | High efficiency hydrophilic aluminum foll finned type | |||||

| m³/h Flow | 50000 | 60000 | 100000 | 120000 | 150000 | 180000 | |

| Protection System | Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. | ||||||

Dimension | L(mm) | 3200 | 3300 | 4400 | 3850 | 4750 | 5850 |

| W(mm) | 1450 | 2300 | 2300 | 2200 | 2200 | 2200 | |

| H(mm) | 2150 | 2400 | 2400 | 2350 | 2450 | 2450 | |

| Wight | kg | 2300 | 2480 | 3800 | 3300 | 4000 | 5000 |

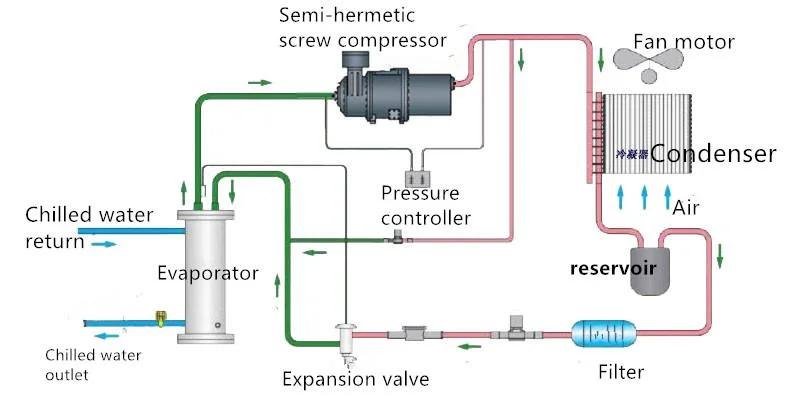

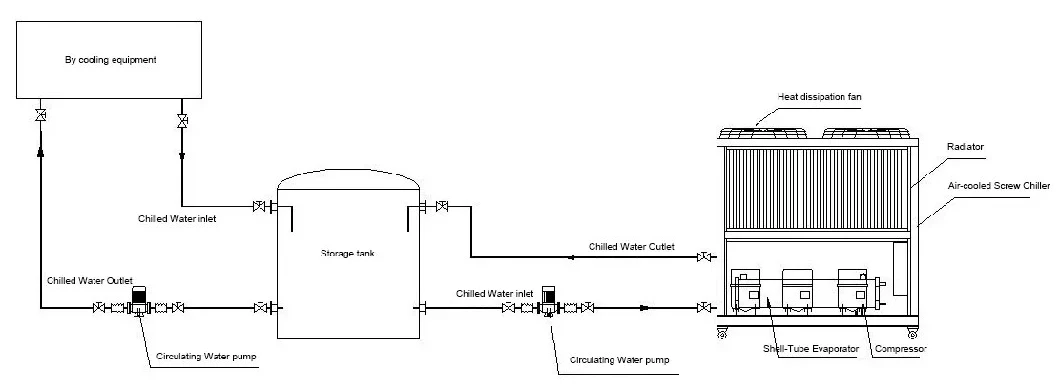

2. Sturcture Drawing 50 Tons 60 Tons 100 Tons Extrusion Molding Processing Cooling Water Air Cooled Chiller

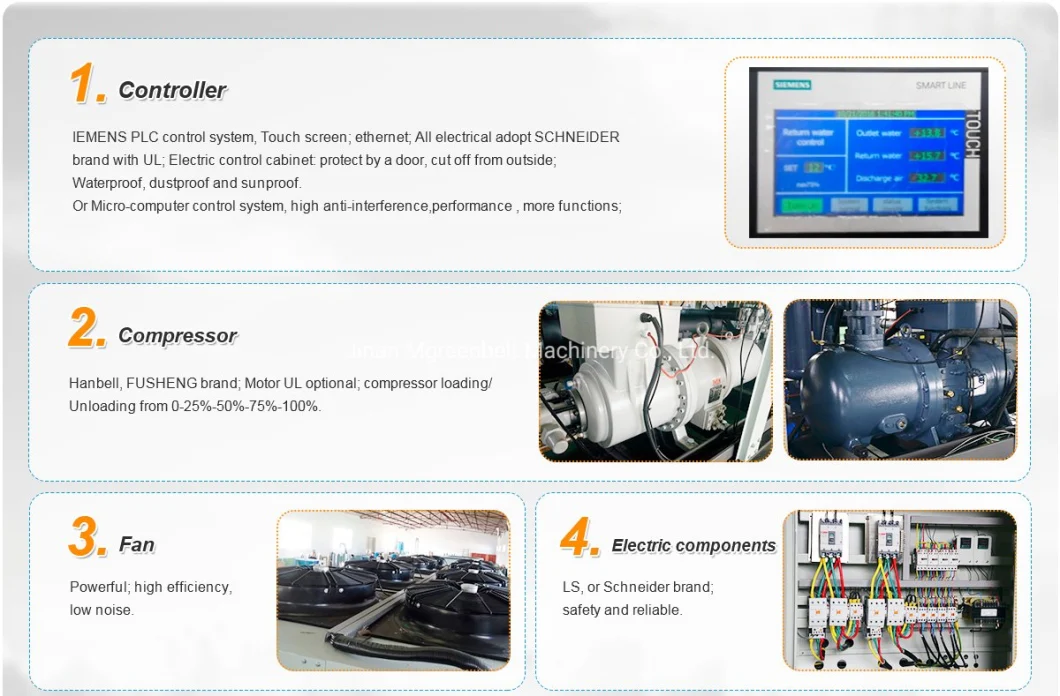

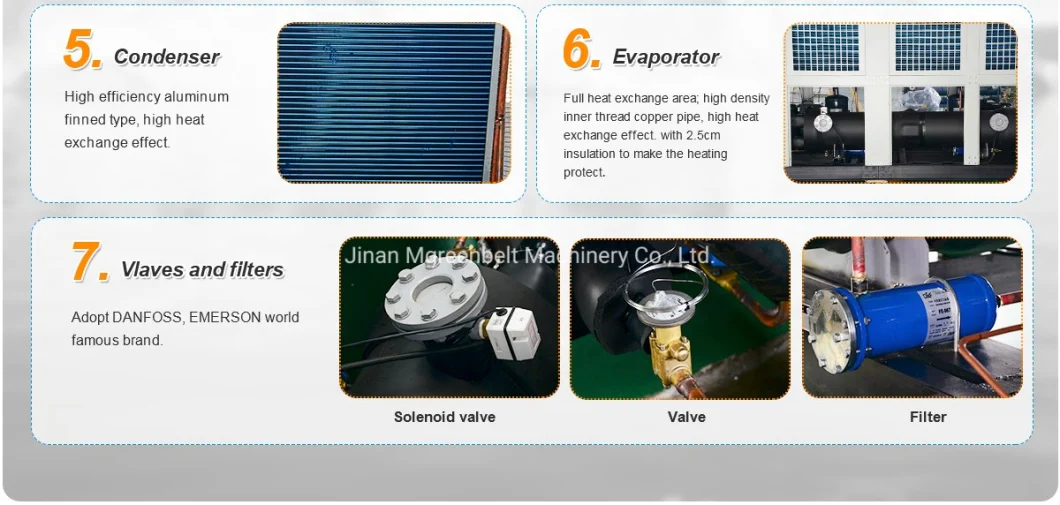

3. Specification Details Images

50 Tons 60 Tons 100 Tons Extrusion Molding Processing Cooling Water Air Cooled Chiller

Hanbell / Bitzer Compressor

The choice of Taiwan HANBELL or Germany Bitzer screw compressor, the use of high-quality bearings, standard operating conditions under the design of the operating life of more than 50,000 hours, optional single compressor / double compressor.

FCNP Pump Industry

FCNP Stainless steel pump. With high lift, large flow, low energy consumption, smooth and reliable operation, high efficiency and lower fault, low vibration noise, long life and other advantages, to ensure that water quality away from corrosion.

Some merchants in order to save costs, will be equipped with poor performance of the water pump, will cause the machine cooling effect is not good, operation is unstable, the chance of repair is high and so on. We use FCNP stainless steel pumps to make the machine more durable and better.

Evaporator core corrosion resistance, good thermal conductivity, high temperature, heat exchange performance, non-polluting media (non-toxic), not easy to scale, non-magnetic, not easy to leak. The inner core adopts a high-strength sealing structure, which is sealed well and increases heat exchange performance.

Microcomputer Control System Or SIMENS PLC Control System

The intelligent control system of microcomputer is precisely controlled, Simple operation, intelligent start and stop, Precision temperature control within 5 to 45 degrees of arbitrary adjustment, LCD display, all kinds of faults at a glance, Monitor ingends in real time, Multiple protection features, The Chinese and English interface sits to switch, To meet the needs of different users, Easy to operate.

Schneider Electrical Systems

50 Tons 60 Tons 100 Tons Extrusion Molding Processing Cooling Water Air Cooled Chiller

Hanbell / Bitzer Compressor

The choice of Taiwan HANBELL or Germany Bitzer screw compressor, the use of high-quality bearings, standard operating conditions under the design of the operating life of more than 50,000 hours, optional single compressor / double compressor.

FCNP Pump Industry

FCNP Stainless steel pump. With high lift, large flow, low energy consumption, smooth and reliable operation, high efficiency and lower fault, low vibration noise, long life and other advantages, to ensure that water quality away from corrosion.

Some merchants in order to save costs, will be equipped with poor performance of the water pump, will cause the machine cooling effect is not good, operation is unstable, the chance of repair is high and so on. We use FCNP stainless steel pumps to make the machine more durable and better.

Evaporator core corrosion resistance, good thermal conductivity, high temperature, heat exchange performance, non-polluting media (non-toxic), not easy to scale, non-magnetic, not easy to leak. The inner core adopts a high-strength sealing structure, which is sealed well and increases heat exchange performance.

Microcomputer Control System Or SIMENS PLC Control System

The intelligent control system of microcomputer is precisely controlled, Simple operation, intelligent start and stop, Precision temperature control within 5 to 45 degrees of arbitrary adjustment, LCD display, all kinds of faults at a glance, Monitor ingends in real time, Multiple protection features, The Chinese and English interface sits to switch, To meet the needs of different users, Easy to operate.

Schneider Electrical Systems

Protection system built-in compressor superload protector, circulating water pump superload, system high and low pressure protector, compressor start electronic time delay, German SIEMENS electronic products, with a sound electrical protection system.

50 Tons 60 Tons 100 Tons Extrusion Molding Processing Cooling Water Air Cooled Chiller

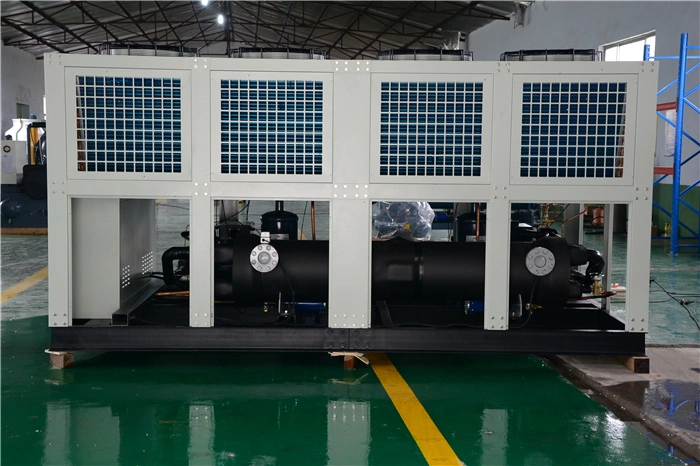

4. Water Chiller Show

5.Chiller Application

6.Model selection parameter

If you are a plastic injection/ extruder, molding industry user, please tell us:

(1). What's your plastic machine type, what's the capacity.

(2). What's the materials you are using, PVC, PE, PP, or others.

Then we will suggest your a right model.

If you are used for other industry, please provide following parameters, MGREENBELT sales will choose the suitable machine for you.

(1).What is the maximum cooling capacity(KW/kcal/h) you need?

(2).What's your inlet and outlet temperature need?

(3).What's your voltage ?Including frequency and Hertz

(4).What's your choice of refrigerant? R22/R407c/R134a or others?

(5).What is the max ambient temperature in your country?

If you are a plastic injection/ extruder, molding industry user, please tell us:

(1). What's your plastic machine type, what's the capacity.

(2). What's the materials you are using, PVC, PE, PP, or others.

Then we will suggest your a right model.

If you are used for other industry, please provide following parameters, MGREENBELT sales will choose the suitable machine for you.

(1).What is the maximum cooling capacity(KW/kcal/h) you need?

(2).What's your inlet and outlet temperature need?

(3).What's your voltage ?Including frequency and Hertz

(4).What's your choice of refrigerant? R22/R407c/R134a or others?

(5).What is the max ambient temperature in your country?

How can I place an order?

1. Please send inquiry to us ! Click " Contact Now"

2. Contact us by call, please find our information at " Contact Us"

3. Or you can contact our sales, Miss Grace Zhang,

3. Or you can contact our sales, Miss Grace Zhang,